Renovation | "Staatl. Kurhausbad" Bad Kissingen

Old building given a new face

A building with tradition, history and stories has been given a new lease of life - and, moreover, usefulness. The neglected Kurhausbad has been elegantly and cleverly transformed into the "House for Health Management" and Bad Kissingen, Germany's best-known spa town, thus retains another piece of time-honoured structure.

Vacancy - ideas for conversion

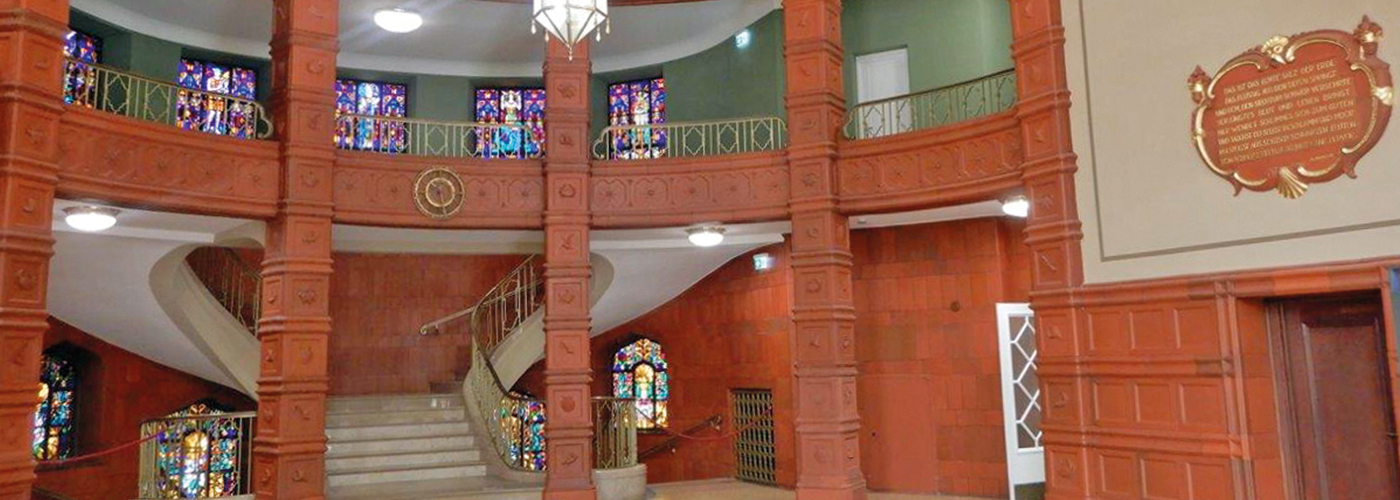

The "Staatliches Kurhausbad" (state spa baths) in Bad Kissingen was the largest of its kind in Europe in 1927 and is now a listed building. From around the middle of the 19th century into the 20th century, it was regularly enlarged; it was extended and rebuilt to meet the requirements of a growing bathing business. During this time, the architectural style changed from historicism to art nouveau. The architectural features of the former bathhouse, which are now rightly listed, are the leaded windows in the staircase, the reddish terracotta panelling in the foyer as well as the interior walls made of Nymphenburg porcelain and the Roman-Irish steam bath.

After a long period of vacancy, ideas were needed for the use of the property. The Free State of Bavaria preferred to sell the building and convert it into a government centre: As part of the "Master Plan for Bad Kissingen" - in addition to the renovation of two other state-owned buildings - the Kurhausbad was to house the offices for the Bavarian State Office for Health and Food Safety (LGL).

New spaces, new perspectives

When a property is converted, the requirements for the existing building, i.e. masonry, existing old plaster and the structural parameters such as heat, sound or fire protection, are changed significantly. Walls are demolished, maxit interior renovation areas are replaced with other building materials and other room distributions are created. A uniform surface must be generated from these conversions and the various masonry materials, e.g. natural stone, existing bricks, new bricks and existing plasters.

In addition to the various substrates, the plaster itself or the binding agent of the plaster plays a major role in plastering. In the case of the spa baths, maxit ip 380 purcalc (lime plaster) was chosen for the interior and partition walls. The water absorption capacity and the water permeability of the plaster allow for a good climate in the rooms.

The exterior walls were provided with interior insulation made of the mineral insulating plaster maxit ip 76 therm. It ensures an increase in the interior wall temperature and a reduction in the heat transfer in the exterior walls. Afterwards, this render was plastered with a filler made of maxit multi 270 S and the surface was felted.

In the vaulted ceilings, the predominantly still load-bearing plaster was left in place. These areas were reworked by priming and levelling the unevenness with maxit multi 270 S. Finally, these areas were smoothed with maxit ip 178 purcalc.