1908 – Or how it all began

The foundation of success of the maxit Group was laid in 1908. Johann Bergmann founded the company Bergmann Kalk and built a lime kiln for the manufacture of heavy concrete blocks, window sills and cement tiles. Year on the year the company grew and step by step expanded its production plants. In 1973 a modern, gas-operated, multi-chamber shaft kiln was erected at the Azendorf site.

Still today the company covers a large share of the raw material demand of the maxit Group.

1978 – The foundation of Franken Maxit

In 1978, Franken Maxit GmbH & Co. was founded as a cooperation between the lime works Bergmann from Azendorf and Mathis from Merdingen and the construction of a dry mortar plant was started.

The conditions for the production of dry mortar could not have been better. While Jura limestone is quarried at Bergmann Kalk in Azendorf and refined into limestone sand and hydrated lime, Franken Maxit processes these raw materials into dry ready-mixed mortar and markets them in transport silos. In transport silos with practice-oriented processing technology or as bagged goods for the building materials trade, the signs for sales are set for success right from the start.

1984 – Lime-cement plaster

In 1984 both lime-cement and lime-gypsum machine-applied plaster were manufactured at the Azendorf site. The demand for the raw material gypsum was at that time covered by the gypsum factory in the Thurinigan Krölpa across the then border to the DDR. The gypsum factory in Krölpa would gain essential significance over the coming years.

1989/90 – Foundation of maxit Baustoffwerke

The political developments in Germany open up new possibilities, even in the construction industry. maxit paves the way for a successful future and in 1990 takes over the gypsum factory in Krölpa with all of its staff in trust and founds the subsidiary maxit Baustoffwerke GmbH. This presents a strategically significant decision for the raw material base within the company: alongside lime both gypsum and anhydrite are available for further processing. This way it was possible to create ideal conditions for the market development into the new Federal States.

In the same year at the Azendorf site another compounding factory is put into operation. With this, capacity rose to approx. 100,000 tonnes of material per year.

1994 – Another factory is erected in Thörey

Another dry mortar plant is built in Thörey near Erfurt. Following the establishment of the Leupahn site, maxit takes advantage of the promising conditions for long-term expansion once again in Thörey.

In the same year, maxit starts supplying dry mortar and mixtures for the construction industry in the Czech Republic. Another branch is founded in Cheb to coordinate cross-border business.

1996 – The dry mortar factory in Niederwinkling is built

Another dry mortar plant is being built in Niederwinkling in Lower Bavaria. With the construction of the new plant, which is conveniently located between Straubing and Deggendorf, maxit expands its sales area to the south. Two years later, maxit additionally strengthens the Niederwinkling site by building a pearlite plant.

The company also grows at the maxit Group's existing locations: A second lime shaft kiln is built at the maxit headquarters in Azendorf, Upper Franconia. At the Krölpa site, the existing dry mortar plant for gypsum plaster and anhydrite flowing screed is expanded to include a grinding plant for the further processing of anhydrite.

1998/99 – Anniversary: 90 years Bergmann-Kalk, 20 years Franken Maxit

Great events shape our future. 1998 is the year of our anniversary. 90 years of Bergmann Kalk and 20 years of Franken Maxit clearly meant it was time to celebrate. During these years, the maxit insulation and façade technology received its own management with a warehouse in Kahla. The Niederwinkling site is further enhanced with the construction of a pearlite plant.

2000/01 – The factories in Dresden and Plattling are taken over

At the turn of the millennium, maxit took over both of the dry mortar factories in the Saxon Dresden and in the Bavarian Plattling from Heidelberg Cement. For the Dresden site this means a step to increasing the impact in Saxony and Thuringia in an already existing sales territory of the maxit Baustoffwerke GmbH. The factory in Dresden is thereby the fourth maxit site in the Federal States of Saxony and Thuringia.

With the Plattling site, maxit is strengthening its presence in Lower Bavaria.

In Czech Republic an independent subsidiary is founded, maxit s.r.o. To optimise logistics in the Czech sales territory, a warehouse is opened in Beroun, on the doorstep of the Czech capital Prague. Simultaneously, at the parent location, Azendorf, a new pearlite plant is put into operation.

2003 – Foundation of the Nuremberg branch

Niederwinkling experiences another sustainable reinforcement as a location of the maxit Group. The opening of a newly erected training centre and a year thereafter the expansion with a plant for the manufacture of bagged goods.

With the foundation of a new branch in Nuremberg, maxit can supply the Nuremberg metropolitan region quickly, without complication in its 25th year of existence.

In the same year, maxit makes strategic switches in Czech Republic. The Eger site is relocated to an already existing warehouse in Beroun near Prague.

2008 – 30 years Franken Maxit

30 years after the founding of Franken Maxit, maxit is able to proudly look back on what they have achieved. The successful establishment of numerous locations and continual growth in the number of employees are confirmation for maxit of the implemented course and simultaneously the commitment for a sustainable design of the future of the company.

Franken Maxit will gain a new partner this year. The Saint Gobain Group will become partners of Franken Maxit and in doing so will relieve Heidelberger Cement and the Mathis lime factory.

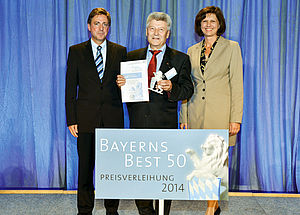

2014 – maxit becomes BAYERNS BEST 50

Great honour for maxit: The Bavarian Ministry of Economic Affairs awards maxit as BAYERNS BEST 50 company. As one of only 50 medium-sized companies in the Free State, the company's constant growth, economic foresight and job creation are honoured.

Minister of State Ilse Aigner presents the certificate and the award in the form of a Bavarian lion to Managing Partner Hans-Dieter Groppweis in the Kaisersaal of the Munich Residence.

2015 – Furore for the maxit Mörtelpad

The mortar specialists from Franken Maxit took part in the world's leading trade fair "BAU 2015" in Munich and presented their new product: the "maxit Mörtelpad". The number of visitors to the stand and the interest in the innovative product clearly exceeded the company's expectations - at times, the aisles around the maxit stand were impassable during the live demonstrations.

Learn more at: www.maxit-moertelpad.de

2016 – A research and development centre is erected

With the presentation of the revolutionary new “maxit mörtelpad”, a dry pad of mortar, which is first moistened on the masonry, maxit provided the international leading trade fair for the building industry and architecture with furore and high press presence

At the Azendorf location, the signs meanwhile remain on expansion. Maxit presses ahead with its innovative company focus for the ground-breaking ceremony for the construction of a new research and development centre. The new-build of a state-of-the-art PFR lime kiln, which is over 60 metres high through the Bergmann Kalk company also ensures the highest quality raw materials for innovative building materials within the maxit Group in future.

2018 – maxit ecosphere: The bang in the insulation market

At maxit, innovation has been a top priority for years - not only in our corporate philosophy, but also in our day-to-day activities. At the world's leading trade fair BAU 2019 in Munich, the Franconian mortar specialist will be presenting its latest innovation: ecosphere mineral pointed insulation. The revolutionary combination of glass and the latest mortar technology not only inspires the specialist public. The Bavarian State Minister for Economic Affairs, Regional Development and Energy, Hubert Aiwanger, also took a guided tour of the trade fair stand by the Groppweis family of entrepreneurs.

2020 – Nomination for the Deutscher Zukunftspreis

Building material meets Federal President. Maxit's head of research Friedbert Scharfe and his partners entered the race for the Deutscher Zukunftspreis 2020 for the development of the mineral spray insulation "ecosphere". Although it was not quite enough to win the coveted trophy in the end, the nomination alone is a great honour: an application for the prize is excluded, and only those who have been nominated by an expert institution and selected by the prize jury are nominated. At the official award ceremony in Berlin by Federal President Frank-Walter Steinmeier on 25 November, the team behind the innovative insulation material was therefore grateful and proud.

2021 – maxit Strohpanel: Ecological alternative in drywall construction

And once again, the building material specialists at maxit have developed something special: "maxit strohpanels", straw carrier boards for drywall construction. They were designed for interior use, where, in combination with lime or clay plasters, they ensure special living comfort and optimal moisture regulation.

The innovative maxit strohpanels are fireproof, extremely durable, industrially compostable and significantly lighter than comparable interior plaster carrier boards.

Further information is available at: www.maxit-strohpanel.de

2022 – The 4th generation of entrepreneurs

With Julia Groppweis joining the family business, the 4th generation is now complete.

Sebastian Groppweis, the eldest of the three siblings, joined the Bergmann-maxit Group back in 2011 and was appointed Managing Director of Bergmann Kalk in 2018. In the same year, his younger sister Katharina Straßburger-Groppweis also followed her entrepreneurial roots. She is now an authorised signatory and manages the Human Resources and Organisation department.